How To Make a Bomber Jacket?

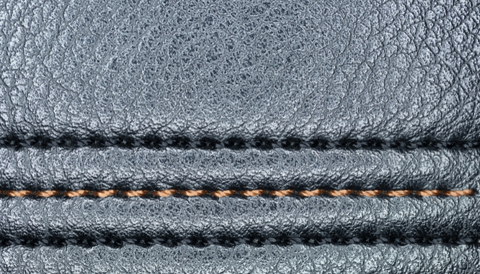

Bomber jackets have stood the test of time as a timeless fashion statement, blending style with functionality. Crafted meticulously from high-quality materials, they epitomize elegance and durability. For enthusiasts seeking a unique touch, creating it using the finest leathers offers a fulfilling and rewarding experience. Here, we will discuss how to make a bomber jacket with steps involved in transforming premium leather into a fashion staple.

1. Gather Materials and Measurements

Gathering the right materials and taking accurate measurements is a crucial starting point in the process. Here's how to make a bomber jacket with this initial step:

Materials Needed

- Premium Leather: Choose top-grade leather based on your preference.

- Pattern Paper or Cardboard: Use this to draft your pattern.

- Measuring Tape: Ensure accurate measurements for a well-fitted piece.

- Fabric Scissors or Rotary Cutter: Essential tools for cutting accurately.

- Chalk or Fabric Marker: For marking the pattern.

- Ruler or Straight Edge: For precise measurements and straight lines.

- Sewing Machine with Leather Needles: To stitch the pieces together.

- High-Quality Thread: A thread that complements the leather.

- Zippers, Buttons, Cuffs, Collars, and Hardware: Depending on your design, select these accessories.

Steps to Gather Materials and Measurements

- Choose the Leather: Select the type and colour of leather for your jacket. Consider its weight, texture, and suppleness.

- Create a Pattern: Using pattern paper or cardboard, draft a pattern. Take accurate measurements of the chest, waist, arm length, and shoulder width. Design the panels for the front, back, sleeves, cuffs, and collar based on these measurements.

- Transfer Measurements to Leather: Using a measuring tape and fabric marker or chalk, transfer the pattern measurements onto the fabric.

- Cut the Leather: Using fabric scissors or a rotary cutter cut the leather according to the marked pattern pieces.

- Prepare Additional Materials: Gather all other materials required, including zippers, buttons, cuffs, collars, and hardware, ensuring they complement the chosen design.

- Double-Check Measurements: Before proceeding to stitch the pieces together, recheck all measurements and patterns to avoid errors in assembly.

Gathering materials and taking precise measurements set the foundation for crafting a bomber jacket that embodies elegance and durability and the most important step of “How to make a bomber jacket”. Before reading further, why don't you check out the collection of handmade jackets at the Finest Leathers?

2. Pattern and Cutting

Creating a precise pattern and executing accurate cutting are pivotal stages in crafting bombers. These steps set the foundation for a well-fitted, aesthetically pleasing garment.

Pattern Making

1. Gather Essential Supplies

- Pattern Paper or Cardboard to draw and refine your blueprint before cutting.

- Measuring Tape to Take precise measurements of the chest, waist, arm length, and shoulder width.

- Ruler, Straight Edge, and Marking Tools to create accurate lines and markings on the pattern.

- Drafting Tools such as French curves or other templates for specific curves or angles.

- Design a Blueprint for a reference for your bomber jacket.

2. Draft the Pattern

- Begin by drawing the front and back panels of the jacket.

- Use the measurements obtained.

- Design sleeves separately, considering the arm measurements.

- Draw separate patterns for cuffs, collars, pockets, and any other specific design details.

3. Refine and Test

- Ensure accuracy by cross-verifying the measurements and proportions.

- If possible, create a mock-up using inexpensive fabric to test the pattern's fit.

Cutting Process

1. Prepare the Leather

- Place the pattern pieces on the leather, considering the grain and any natural imperfections or markings.

- Use weights or small clips to secure the pattern pieces in place before cutting.

2. Cutting Techniques

- Use sharp fabric scissors or a rotary cutter for clean, accurate cuts.

- Exercise caution and patience while cutting.

- Follow the marked lines precisely to avoid errors.

3. Organize Cut Pieces

- As you cut each pattern piece, label or mark them to easily identify their position.

- Retain any smaller leather pieces as they might be useful in the future.

The precision and accuracy involved in pattern-making and cutting are fundamental to crafting bombers. Attention to detail during these initial stages lays the groundwork for a well-constructed and visually appealing garment.

Also, check out our collection of black leather bomber jackets to level up your swag!

3. Assemble and Sew

Assembling and sewing the leather pieces of a bomber jacket is a crucial stage that requires attention to detail, precision, and skilled craftsmanship.

Prepare Work Area and Materials

- Sewing Machine: Ensure it's equipped with a leather needle and appropriate thread for leather.

- Leather Adhesive or Clips: Use these to temporarily secure pieces before stitching.

- Rubber Mallet or Leather Hammer: Helps flatten seams and ensure they lay flat.

- Work Table: A spacious, clean, and flat surface to assemble the garment.

Arrange the Pieces

- Lay Out Panels: Place the pieces according to the pattern and design layout.

- Temporary Securing: Use clips or adhesive to temporarily secure the pieces.

Sewing Process

- Set Up the Sewing Machine: Install a needle designed for heavy fabrics and test on a scrap piece of to ensure the settings are appropriate for your material.

- Stitching Techniques: Begin sewing the panels together, starting with the main seams such as the shoulders, sides, and sleeves. Backstitch at the beginning and end of each seam for reinforcement.

- Handle Curves and Corners: Take your time when sewing around curves and corners to maintain precision and prevent puckering. Flatten seams after stitching, especially around curves, to ensure they lay flat for a polished look.

Assembling and sewing the leather pieces of a bomber jacket demands patience, precision, and attention to detail. This stage brings the individual components together to form a cohesive, stylish garment. Also, check out our collection of men’s leather jackets for better options!

4. Zipper Installation

Installing a zipper requires precision and attention to detail for a secure and aesthetically pleasing finish.

Materials and Tools Needed

- Quality Zipper

- Fabric Marker or Chalk

- Ruler or Measuring Tape

- Sewing Machine with Zipper Foot

- Heavy-Duty Thread

- Scissors or Rotary Cutter

Steps for Zipper Installation

- Mark the Zipper Placement: Lay the jacket flat and ensure the edges where the zipper will be installed are perfectly aligned. Use a fabric marker or chalk to draw straight, parallel lines.

- Prepare the Zipper: If needed, trim the zipper to fit the length of the marked lines. Use double-sided tape or pins to temporarily secure it in place along the marked lines.

- Install the Zipper: Place the zipper foot onto the sewing machine for easier stitching. Sew over it multiple times for added strength and security, especially at the top and bottom stops.

- Test the Zipper: After sewing, test it to ensure it opens and closes smoothly without any snags or issues.

Installing a zipper requires precision and careful stitching to seamlessly integrate it into the garment! Our collection of women’s leather jackets would be the best choice if you like fancy zippers!

5. Finish and Quality Check

Completing the finishing touches and conducting a thorough quality check are crucial steps to make sure your garment is impeccably crafted and meets the highest standards.

Finishing Touches

- Trim Excess Threads and Materials: Use sharp scissors to carefully trim any loose or excess threads from seams and stitching for a clean and polished appearance.

- Check for Imperfections: Examine all seams and stitching for any missed spots, loose threads, or irregularities. If you find any issues, address them by making necessary adjustments.

- Pressing and Ironing: Use a leather-specific iron or apply gentle pressure with a damp cloth to press and flatten seams without damaging the fabric.

Quality Check

- Fit and Functionality: Verify that the garment fits according to the intended design specifications. Zippers, buttons, pockets, and other components function smoothly without any issues.

- Structural Integrity: All seams are secure and even, without any weak spots or loose stitching. Confirm that edges are clean, trimmed, and free from fraying or unevenness.

- Aesthetic Appeal: Evaluate the jacket's appearance for a professional and polished look.

- Durability and Longevity: Assess the overall durability, checking for any potential weak points that may need reinforcement.

Final Inspection

The last important step for “How to make a bomber jacket” is the final inspection. Make sure that it fits comfortably and looks as expected when worn. If possible, have a skilled tailor or leather craftsman review it for any overlooked details or potential improvements. Also, check out our Rose Gold Leather Jacket!

Finest Leathers - Where Fashion Meets Expertise

How to make a bomber jacket? - Crafting it from the finest leathers is a labour of love that requires skill, precision, and an eye for detail. Each step in the process contributes to creating a garment that embodies sophistication and durability. At Finest Leathers, our commitment to using premium materials and expert craftsmanship ensures that each bomber jacket produced is a testament to luxury and style.

Whether for personal use or as a statement piece, custom-made bombers offer a unique blend of individuality and elegance. With dedication and attention to detail, the process of creating this iconic garment becomes an art form, resulting in a timeless piece that stands out in any wardrobe. FINEST LEATHERS stands as a testament to unparalleled quality, where each stitch and detail speaks volumes about our dedication to excellence!

Leave a comment